BUTTERFLY VALVES

A butterfly valve is a widely used device in fluid control systems designed for regulating the flow of liquids or gases through a pipe. It operates using a circular disc that rotates around a central axis within the valve body, allowing or blocking flow based on its position. Butterfly valves are ideal for applications requiring precise flow control or reliable isolation of flow. Butterfly valves provide excellent efficiency in controlling flow rates and are particularly effective in situations where space-saving designs are essential.

Butterfly valves are a crucial component in many systems due to their versatility and cost-effectiveness, serving as an optimal solution for controlling flow in pipelines. Commonly found in industries such as water supply, oil and gas, chemical processes, and power generation, butterfly valves are essential for managing both small and large volumes of fluid securely.

PR-FECT VALVES manufactures butterfly valves in a wide range of sizes, materials, and pressure ratings, ensuring compatibility with diverse industrial applications and offering advanced technical features such as precision-engineered discs and corrosion-resistant coatings for enhanced performance and durability.

| SL. NO. | BUTTERFLY VALVE TYPES |

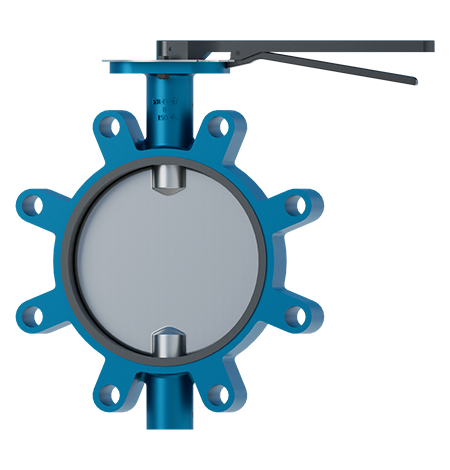

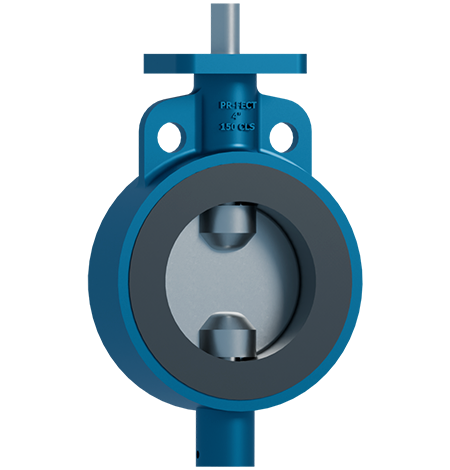

| 1 | CONCENTRIC BUTTERFLY VALVE |

| 2 | DOUBLE ECCENTRIC BUTTERFLY VALVE |

| 3 | TRIPLE OFFSET BUTTERFLY VALVE |

| 4 | CONTROL BUTTERFLY VALVE |

| 5 | BUTTERFLY DAMPER |

| 6 | CRYOGENIC BUTTERFLY VALVE |

| 7 | HIGH PERFORMANCE BUTTERFLY VALVE |

| 8 | HIGH CYCLE BUTTERFLY VALVE |

| 9 | EMERGENCY SHUT DOWN BUTTERFLY VALVE |

| 10 | GAS-TIGHT BUTTERFLY VALVE |

| 11 | HIGH TEMPERATURE BUTTERFLY VALVE |

| 12 | BRONZE BUTTERFLY VALVE |

| 13 | FABRICATED BUTTERFLY VALVE |

| 14 | PVC / CPVC BUTTERFLY VALVE |

| 15 | HIGH PRESSURE BUTTERFLY VALVE |

| 16 | SUBSEA BUTTERFLY VALVE |

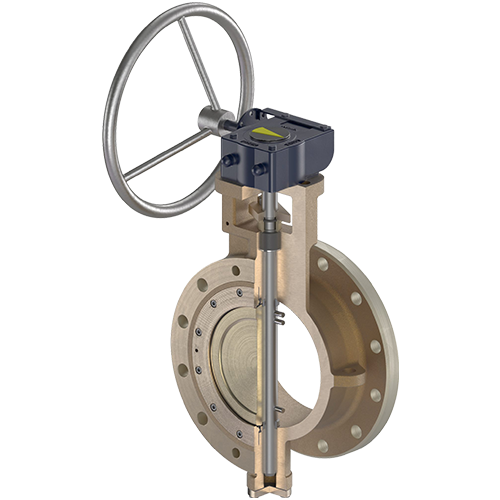

| 17 | EXTENSION SPINDLE BUTTERFLY VALVE |

| PRODUCT DETAILS | |

| Sizes | 1/4" to 250" |

| Pressure Class Ratings | Asme #150, PN6, PN10, PN20, PN25 |

| End Connection | Wafer, Lugged, Flanged |

| Construction Types | Centric Disc |

| Salient Features | One-piece blowout-proof Stem, Reliable Drive Operation, Low Torque, Assured Sealing, Integral Actuator Mounting, Stem Extension, Locking Arrangements etc. |

| Operator / Actuator | Handwheel, Gear, Actuator (Pneumatic, Hydraulic, Electro-Hydraulic and Electric Motorised) |

| STANDARDS SPECIFICATIONS | |

| Design & Manufacture | EN 593 (BS 5155), API 609, MSS SP 67, ISO 5752 |

| Face To Face | API 609, MFG Standard |

| End Connections | ASME B 16.1 Class 125, B 16.5 Class 150, EN 1092-2, BS 4504, BS 10 Table D & E |

| Testing | EN 12266/ API 598 |

| Fire safe testing | |

| Nace | NACE MR0175 / ISO 15156 and NACE MR0103 / ISO17945 |

| Fugitive emission | |

| MATERIAL OF CONSTRUCTION | |

| Body | Cast Iron, SG Iron, Carbon & Low Carbon Steel, Stainless Steel, Nickel alloys, High Temp Alloys, Duplex Stainless Steel, Exotic Materials |

| Body Liner | Nitrile, EPDM, Viton etc. |

| Disc | Cast Iron, SG Iron, Stainless Steel, Nickel alloys, Duplex Stainless Steel, Exotic Materials |

| Bearing | Acetal, PTFE, Phosphor Bronze |

| Stem | Stainless Steel, Nickel alloys, Duplex Stainless Steel, Exotic Materials |

Note : For Bigger sizes please contact PR-Fect Valves