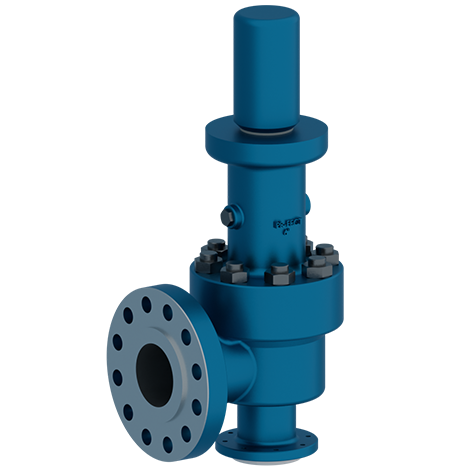

RELIEF VALVES

A relief valve is a critical device in fluid control systems designed to prevent overpressure conditions that could damage equipment or pose safety risks. It operates by automatically opening when the pressure in a system exceeds a predefined limit, allowing excess fluid or gas to escape and reducing pressure to safe levels. Relief valves are indispensable in applications requiring reliable protection against pressure surges or unexpected system failures.

Relief valves are a vital component in many systems due to their ability to safeguard equipment and ensure operational safety. Commonly found in industries such as water supply, oil and gas, chemical processes, and power generation, relief valves are essential for maintaining system integrity under varying conditions and protecting both small and large-scale installations.

PR-FECT VALVES manufactures relief valves in a wide range of sizes, materials, and pressure ratings, ensuring compatibility with diverse industrial applications and offering advanced technical features such as precision-machined components and corrosion-resistant coatings for enhanced performance and durability.

| SL. NO. | RELIEF VALVE TYPES |

| 1 | SAFETY RELIEF VALVE |

| 2 | PILOT OPERATED SAFETY RELIEF VALVE |

| 3 | BELLOWS SEAL SAFETY RELIEF VALVE |

| 4 | HIGH EFFICIENCY PILOT-OPERATED SAFETY RELIEF VALVE |

| 5 | COMPACT PERFORMANCE SAFETY RELIEF VALVE |

| 6 | HIGH PERFORMANCE SAFETY RELIEF VALVE |

| 7 | MODULATE ACTION SAFETY RELIEF VALVE |

| 8 | CLEAN SERVICE SAFETY RELIEF VALVE |

| 9 | CRITICAL SERVICE SAFETY RELIEF VALVE |

| 10 | SURGE RELIEF VALVE |

| 11 | AIR RELIEF VALVE |

| 12 | VACUUM RELIEF VALVE |

| 13 | PRESSURE RELIEF VALVE |

| 14 | PILOT OPERATED PRESSURE RELIEF VALVE |

| 15 | BELLOWS SEAL PRESSURE RELIEF VALVE |

| 16 | HIGH EFFICIENCY PILOT-OPERATED PRESSURE RELIEF VALVE |

| 17 | COMPACT PERFORMANCE PRESSURE RELIEF VALVE |

| 18 | HIGH PERFORMANCE PRESSURE RELIEF VALVE |

| 19 | MODULATE ACTION PRESSURE RELIEF VALVE |

| 20 | CLEAN SERVICE PRESSURE RELIEF VALVE |

| 21 | CRITICAL SERVICE PRESSURE RELIEF VALVE |

| PRODUCT DETAILS | |

| Sizes | 1/4" to 250" |

| Pressure Class Ratings | ASME #150 to #4500 |

| End Connection | Screwed, Socket Weld, Flanged |

| Construction Types | Self Actuation |

| Salient Features | High Stable Flow coefficient, Metal Seats, Bellow Seal, Locking Arrangements etc. |

| Operator / Actuator | Adjustment Screw, Lever, , others upon request |

| STANDARDS SPECIFICATIONS | |

| Design & Manufacture | API 526, ASME B16.34 |

| Face To Face | API 526, MFG Standard |

| End Connections | ASME B16.11, ISO 7-1, BS 21 ASME B1.20.1, ASME B16.5/ B16.47 RF/FF/RTJ ASME 16.25, EN 1092 |

| Testing | API 527 |

| Nace | NACE MR0175 / ISO 15156 and NACE MR0103 / ISO17945 |

| MATERIAL OF CONSTRUCTION | |

| Body / Bonnet / Cap | Carbon & Low Carbon Steel, Stainless Steel, Nickel alloys, High Temp Alloys, Duplex Stainless Steel, Exotic Materials |

| Trim | Stainless Steel, Nickel alloys, Duplex Stainless Steel, Exotic Materials |

| Seat | Neoprene, FKM, EPDM, PTFE, HF-Metal to Metal Seats, others upon request |

| Spring | Stainless Steel, Spring Steel, Inconel, Chrome Steel |

| Gaskets | PTFE/ RPTFE/ Special filled PTFE/Graphite/Graphoil |

| Fasteners | ASTM A193 Gr.B7/A194 Gr.2H, B7M/2HM, B8/8, B8M/8M, L7/4, B16/2H etc., |

Note : For Bigger sizes please contact PR-Fect Valves