SPECIAL VALVES

Special valves are versatile devices used in fluid control systems for precise management of liquid or gas flow through pipelines. They operate through advanced mechanisms tailored to specific requirements, offering high performance in regulating, isolating, or directing flow. Special valves are ideal for applications that demand customized solutions for unique operational challenges. These valves provide superior sealing capabilities and exceptional reliability in environments where precision and durability are critical.

Special valves play an integral role in many systems due to their adaptability and efficiency, serving as solutions for intricate flow control scenarios. Found across various industries—including water treatment, oil refinery, pharmaceutical manufacturing, and aerospace engineering—special valves are indispensable for securely managing both small and large volumes of fluid under diverse conditions.

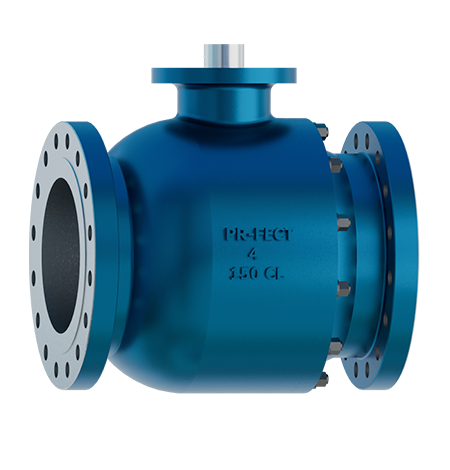

PR-FECT VALVES manufactures special valves in an extensive range of designs, materials, and pressure ratings, ensuring suitability for unique industrial applications. With advanced technical features such as precision engineering, corrosion-resistant technology, and innovative designs. PR-FECT VALVES delivers enhanced performance and durability in specialized operational environments.

| SL. NO. | SPECIAL VALVE TYPES |

| 1 | PIG VALVE |

| 2 | MULTIPORT SELECTOR VALVE |

| 3 | FIXED CONE DISPENSER VALVE |

| 4 | MONOFLANGE VALVE |

| 5 | MANIFOLD VALVE |

| 6 | FOOT VALVE |

| 7 | GOGGLE VALVE |

| 8 | LOUVER DAMPER VALVE |

| 9 | CHOKE VALVE |

| 10 | AXIAL CHOKE VALVE |

| 11 | NEEDLE TYPE CHOKE VALVE |

| 12 | DOME VALVE |

| 13 | FLAP VALVE |

| 14 | BALANCING VALVE |

| 15 | PRESSURE REDUCING VALVE |

| 16 | FLOAT VALVE |

| 17 | SLAM SHUTOFF VALVE |

| 18 | AUTOMATIC RECIRCULATION VALVE |

| 19 | SURGE ANTICIPATING VALVE |

| 20 | FLUSH BOTTOM VALVE |

| 21 | STEAM JACKTED FLUSH BOTTOM VALVE |

| 22 | BLOWDOWN VALVE |

| 23 | INTERMITTENT ANGLE BLOW DOWN VALVE |

| 24 | ANGLE BLOW DOWN VALVE |

| 25 | OPEN BODY PINCH VALVE |

| 26 | CLOSED BODY PINCH VALVE |

| 27 | HAMMER BLIND VALVE |

| 28 | DELUGE VALVE |

| 29 | FIRE HYDRANT VALVE |

| 30 | STEAM TRAP |

| 31 | FLAP TYPE DAMPER |

| 32 | QUICK COUPLING |

| 33 | SIGHT GLASS |

| 34 | VACUUM BREAKER |

| 35 | DISMANTLING JOINT |

| 36 | EXPANSION JOINT |

| 37 | MECHANICAL FLOAT STEAM |

| 38 | SLIMLINE MONOFLANGE |

| 39 | PV. WITH CO2 ABSORBER |

| 40 | 4-WAY DIVERTER VALVE |

| 41 | ANTI-SHOCK VALVES |

| 42 | ANTI VACCUME VALVE |

| 43 | AIR RELEASE VALVE |

| 44 | HF ACID VALVES |

| 45 | SEPTUM VALVES |

| 46 | HYDROGEN SERVICE VALVES |

PRESSURE REDUCING VALVE TECHNICAL SPECIFICATION

| PRODUCT DETAILS | |

| Sizes | 1/4" to 6 " |

| Pressure Class Ratings | Asme #150 to #2500 |

| End Connection | Screwed, Socket Weld, Flanged, Butt-Weld |

| Construction Types | Self Actuation |

| Salient Features | Rugged construction, Metal Seats, Differential Pressure Capability, Cryogenic, Locking Arrangements etc. |

| Operator / Actuator | Adjustment Screw, Handwheel, others upon request |

| STANDARDS SPECIFICATIONS | |

| Design & Manufacture | ASME B16.34 |

| Face To Face | ASME B16.10, MFG Standard |

| End Connections | ASME B16.11, ISO 7-1, BS 21 ASME B1.20.1, ASME B16.5/ B16.47 RF/FF/RTJ ASME 16.25, EN 1092 |

| Testing | ANSI/FCI 70 |

| Nace | NACE MR0175 / ISO 15156 and NACE MR0103 / ISO17945 |

| MATERIAL OF CONSTRUCTION | |

| Body /Spring Case | Carbon & Low Carbon Steel, Stainless Steel, Nickel alloys, High Temp Alloys, Duplex Stainless Steel, Exotic Materials |

| Trim | Stainless Steel, Nickel alloys, Duplex Stainless Steel, Exotic Materials |

| Seat | Neoprene, FKM, EPDM, PTFE, HF-Metal to Metal Seats, others upon request |

| Diaphragm | Neoprene, FKM, EPDM, Metal |

| Gaskets | PTFE/ RPTFE/ Special filled PTFE/Graphite/Graphoil |

| Fasteners | ASTM A193 Gr.B7/A194 Gr.2H, B7M/2HM, B8/8, B8M/8M, L7/4, B16/2H etc., |

Note : For Bigger sizes please contact PR-Fect Valves

FLUSH BOTTOM VALVE & STEAM JACKTED FLUSH BOTTOM VALVE TECHNICAL SPECIFICATION

| PRODUCT DETAILS | |

| Sizes | 1/4" to 12 " |

| Pressure Class Ratings | Asme #125 to #2500 |

| End Connection | Screwed, Socket Weld, Flanged, Butt-Weld |

| Construction Types | Single Piece, Two Piece Constructions |

| Port Options | Full Port & Regular Port |

| Salient Features | Fire-Safe Design, Cryogenic Configuration, Stem Extension, Cavity Pressure Relief mechanism, Antistatic feature, High Integrity Stem Sealing, Blowout-proof stem, Primary Metal and Secondary Soft Seat Design, Locking Arrangements, Internal Lining Etc. |

| Operator / Actuator | Lever, Gear, Actuator (Pneumatic, Hydraulic, Electro-Hydraulic and Electric Motorised) |

| STANDARDS SPECIFICATIONS | |

| Design & Manufacture | API 6D, API 608, ASME B16.34, BS EN ISO 17292 |

| Face To Face | ASME B16.10, MFG Standard |

| End Connections | ASME B16.11, ISO 7-1, BS 21 ASME B1.20.1, ASME B16.5 RF/FF/RTJ ASME 16.25, EN 1092 |

| Testing | API 6D, API 598, ASME B16.34, BS EN 12266, ISO 5208 |

| Fire safe testing | ISO 10497/ API 607, API 6FA |

| Nace | NACE MR0175 / ISO 15156 and NACE MR0103 / ISO17945 |

| Fugitive emission | ISO 15848-1, API 641 |

| Leak tightness | ISO 5208, ANSI/FCI 70-2 |

| MATERIAL OF CONSTRUCTION | |

| Body / End Connector | Carbon & Low Carbon Steel, Stainless Steel, Nickel alloys, Aluminium Bronze, Duplex Stainless Steel, Exotic Materials |

| Trim | Stainless Steel, Nickel alloys, Duplex Stainless Steel, Exotic Materials |

| Seat | PTFE/ RPTFE/ Special filled PTFE/ PEEK/ Devlon®/ SS316 + ST |

| Stem Packing & Seals | PTFE/ RPTFE/ Special filled PTFE/Graphite/Graphoil |

| Gaskets | PTFE/ RPTFE/ Special filled PTFE/Graphite/Graphoil/Spiral Wounded |

| Stem Bearing | RPTFE/ Special filled PTFE/Graphite |

| Fasteners | ASTM A193 Gr.B7/A194 Gr.2H, B7M/2HM, B8/8, B8M/8M, L7/4, B16/2H etc., |

Note : For Bigger sizes please contact PR-Fect Valves

FOOT VALVE TECHNICAL SPECIFICATION

| PRODUCT DETAILS | |

| Sizes | 1/2" to 36" |

| Pressure Class Ratings | Asme #150 to #300 |

| End Connection | Screwed, Flanged |

| Construction Types | Spring Loaded, Disc Type, others upon request |

| Salient Features | Easy Installation, Low Head Loss, High Capacity, Repalcable Seats etc. |

| Operator / Actuator | Self Actuation |

| STANDARDS SPECIFICATIONS | |

| Design & Manufacture | ASME B16.34 |

| Face To Face | MFG Standard |

| End Connections | ISO 7-1, BS 21, ASME B1.20.1, ASME B16.5 RF/FF, EN 1092 |

| Testing | ASME B16.34 |

| Nace | NACE MR0175 / ISO 15156 and NACE MR0103 / ISO17945 |

| MATERIAL OF CONSTRUCTION | |

| Body | Cast Iron, SG Iron, Carbon & Low Carbon Steel, Stainless Steel, Nickel alloys, High Temp Alloys, Duplex Stainless Steel, Exotic Materials |

| Trim | Stainless Steel, Nickel alloys, Duplex Stainless Steel, Exotic Materials |

| Seats | Natural Rubber, Neoprene, Buna-N, Viton, EPDM, PTFE, NBR etc |

| Gaskets | PTFE/ RPTFE/ Special filled PTFE/Graphite/Graphoil/Rubber |

| Fasteners | ASTM A193 Gr.B7/A194 Gr.2H, B7M/2HM, B8/8, B8M/8M, L7/4, B16/2H etc., |

Note : For Bigger sizes please contact PR-Fect Valves

AIR RELEASE VALVE TECHNICAL SPECIFICATION

| PRODUCT DETAILS | |

| Sizes | 1/2" to 12 " |

| Pressure Class Ratings | Asme #150 to #300 |

| End Connection | Screwed, Flanged |

| Construction Types | Single Chamber, Double Chamber others upon request |

| Salient Features | Easy Installation, Low Head Loss, High Capacity, Maximum Pipeline Efficiency etc. |

| Operator / Actuator | Self Actuation |

| STANDARDS SPECIFICATIONS | |

| Design & Manufacture | AWWA C512, EN 1074, ASME B16.34 |

| Face To Face | MFG Standard |

| End Connections | ISO 7-1, BS 21, ASME B1.20.1, ASME B16.5 RF/FF, EN 1092 |

| Testing | ASME B16.34 |

| Nace | NACE MR0175 / ISO 15156 and NACE MR0103 / ISO17945 |

| MATERIAL OF CONSTRUCTION | |

| Body / Cover | Cast Iron, SG Iron, Carbon & Low Carbon Steel, Stainless Steel |

| Trim | Stainless Steel, Bronze, others upon request |

| Seats | Metal, Natural Rubber, Neoprene, Buna-N, Viton, EPDM, PTFE, NBR etc |

| Gaskets | PTFE/ RPTFE/ Special filled PTFE/Graphite/Graphoil/Rubber |

| Fasteners | ASTM A193 Gr.B7/A194 Gr.2H, B7M/2HM, B8/8, B8M/8M, L7/4, B16/2H etc., |

Note : For Bigger sizes please contact PR-Fect Valves